Overview

Industry

Food & Beverages

Region

USA

Duration

8 Weeks

Ethereum

Ethereum Remix

Remix Solidity

Solidity DynamoDB

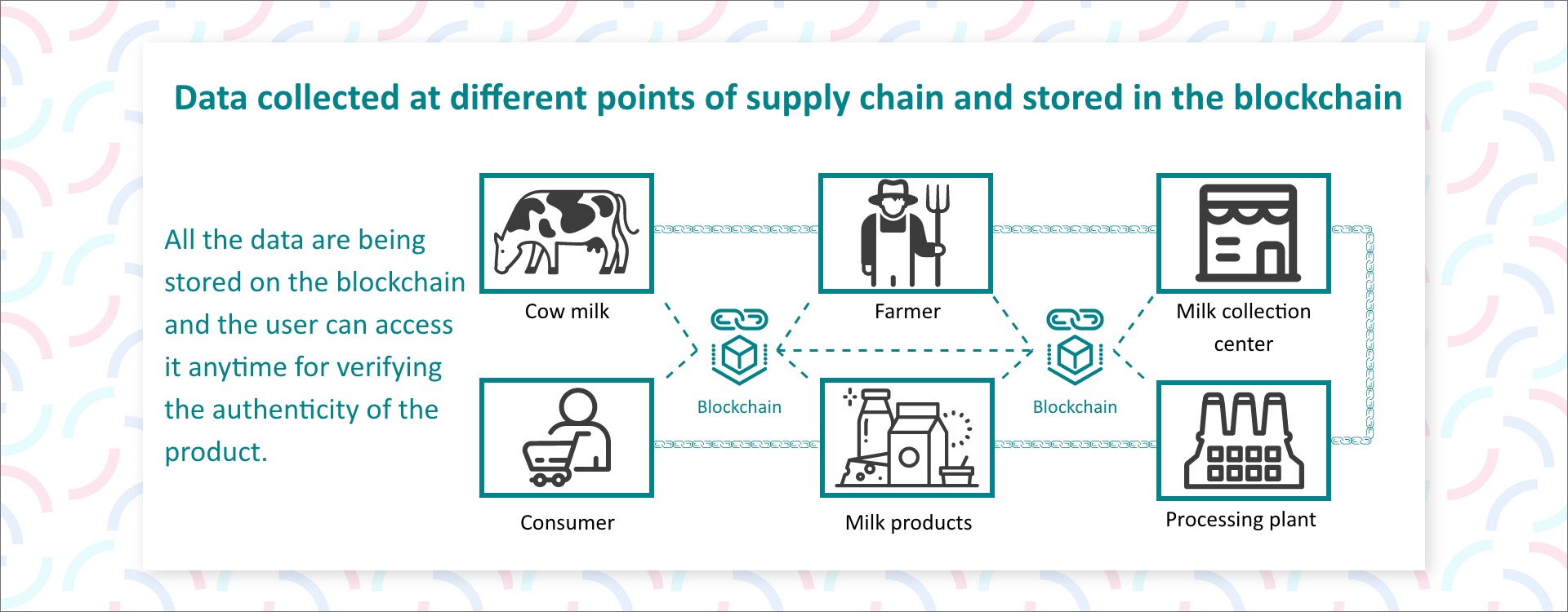

DynamoDBThe client operates in the food and manufacturing sector, specializing in the production of milk-based products.

Let’s transform your idea into a real product with scalable solutions.